| The structure change of Ce-based metallic glasses under high pressure |

| From: PublishDate:2016-06-03 Hits: |

Polyamorphousim has been observed for a long time in some glasses involving directional and open coordination environments (such as ice, silica, silicon and chalcogenide glasses). However, it is not evidenced that the polyamorphous can exist in metallic glasses (MGs) which have a very densely packed structure without directional coordination until the work of Sheng in 2007(Nature 6, 192–197(2007))Nevertheless, the nature of the polyamorphousim in MGs,such as the 4f electron delocalization mechanism and the change of short-to-medium range ordered structures under pressure is poorly understood. Furthermore, it is worth noting that the polyamorphic transformation process in all the previous reported metallic glass systems is gradual and occurs in a broad pressure range. Therefore, whether the polyamorphic transition nature is of first order in the amorphous metallic system is ambiguous.

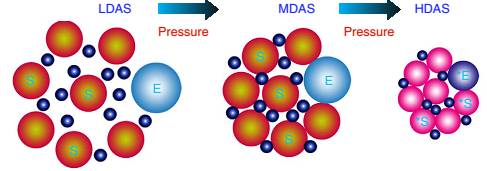

Figure 1. Illustration of hierarchical densification of Ce-based metallic glass. The smallest cyan ball represents the Ce atom, the mediumsized colour (orange and blue) ball represents the solute-centred cluster (S) and the largest colour (orange and blue) ball represents the supercluster (E). Recently, a group in Tongji University reported the densification processes of metallic glass Ce65Co25Al10 (fabricated by melt-spinning technique) under high pressure both at room temperature (293 K) and 390 K, which is near the glass transition temperature (Tg~396 K), using in situ high-pressure synchrotron X-ray measurements performed at Beamline at Beamline 4W2 of the BSRF in Beijing. The group observed a hierarchical densification processes (from low density amorphous state, through medium density amorphous state, to high density amorphous state) at both temperatures, arising from the inherent structural inhomogeneity and hierarchy of interatomic interactions.That is, different degree of contribution from changes of free volume zone, medium range order and short range order. The low density amorphous state-to-low density amorphous state transformation, which primarily is related to the shortening of the weak Ce-Ce bonds among the solute-cantered clusters and does not undergo significant change in short-range order, is similar to the first-order isostructural α-γ transition of pure Ce. In contrast, the medium density amorphous state-to-high density amorphous state transformation, associated with the change of short-range order, is somehow similar to the normal polymorphic transition in crystals involving a distinct change of the unit cell. During the densification process, the special 4f electron delocalization of the Ce atoms assists largely in the bond shortening. Moreover, a relatively discontinuous change of volume is observed around 5.5GPa when the experiment was performed at 390 K, while only a smooth and continuous change is observed at room temperature (293K). The discontinuous change in volume implies a possible first-order-like nature of the polyamorphic transformation, which is hidden thus far in previous experiments due to kinetic sluggishness at lower temperatures. In addition, the Ce65Co25Al10MG shows abnormal-negative thermal expansion under a pressure range of 0.6–9.0GPa, which could arise from a combination of the relaxation (minor role) and tilting or rocking motions of the tightly bonded polyhedral clusters linking to weakest atom zones. The pressure-induced variation of the hierarchical bonding, will exert significant impacts on the mechanical, dynamics and glass transition of various MG systems, due to their strong dependence on both the short range order, medium range order and linkage-atom (free volume) zones. Article: Q. Luo, G. Garbarino, B. Sun, D. Fan, Y. Zhang, Z. Wang, Y. Sun, J. Jiao, X. Li, P. Li, N. Mattern, J. Eckert & J. Shen,Hierarchical densification and negative thermal expansion under high pressure in Ce-based metallic glass. Nature communications 6, 5703-5711(2015). |

|

|

| Chinese

- Beamline 1W1 of BSRF started to runoperate in the couplingparasitic mode of BEPCII

- Synthesis of High Performance Polymer Materials for Field Effect-Transistors

- Surfactant molecular aggregates in green solvents

- GIXRD has played an important role in the characterization of organic thin-film transistors

Copyright © 2011 - 2012 Beijing Synchrotron Radiation Facility